Lessons from the Kobayashi Red Yeast Incident on Food Safety Issues

With technological advancements, the food industry has seen rapid development. However, the core of food production, "food safety," remains an irreplaceable priority. Globally, food safety is receiving increasing attention. The United Nations designated June 7 as "World Food Safety Day" to raise awareness, and our government has implemented the "Five Rings of Food Safety" policy. This aims to ensure comprehensive measures, from source control to public supervision, to improve food safety management. However, food safety cannot solely rely on "experience" or "management processes." Otherwise, even a century-old giant like Japan's Kobayashi Pharmaceutical would not have encountered the toxic red yeast incident. Let us reflect on the key areas for improvement in food safety based on this event.

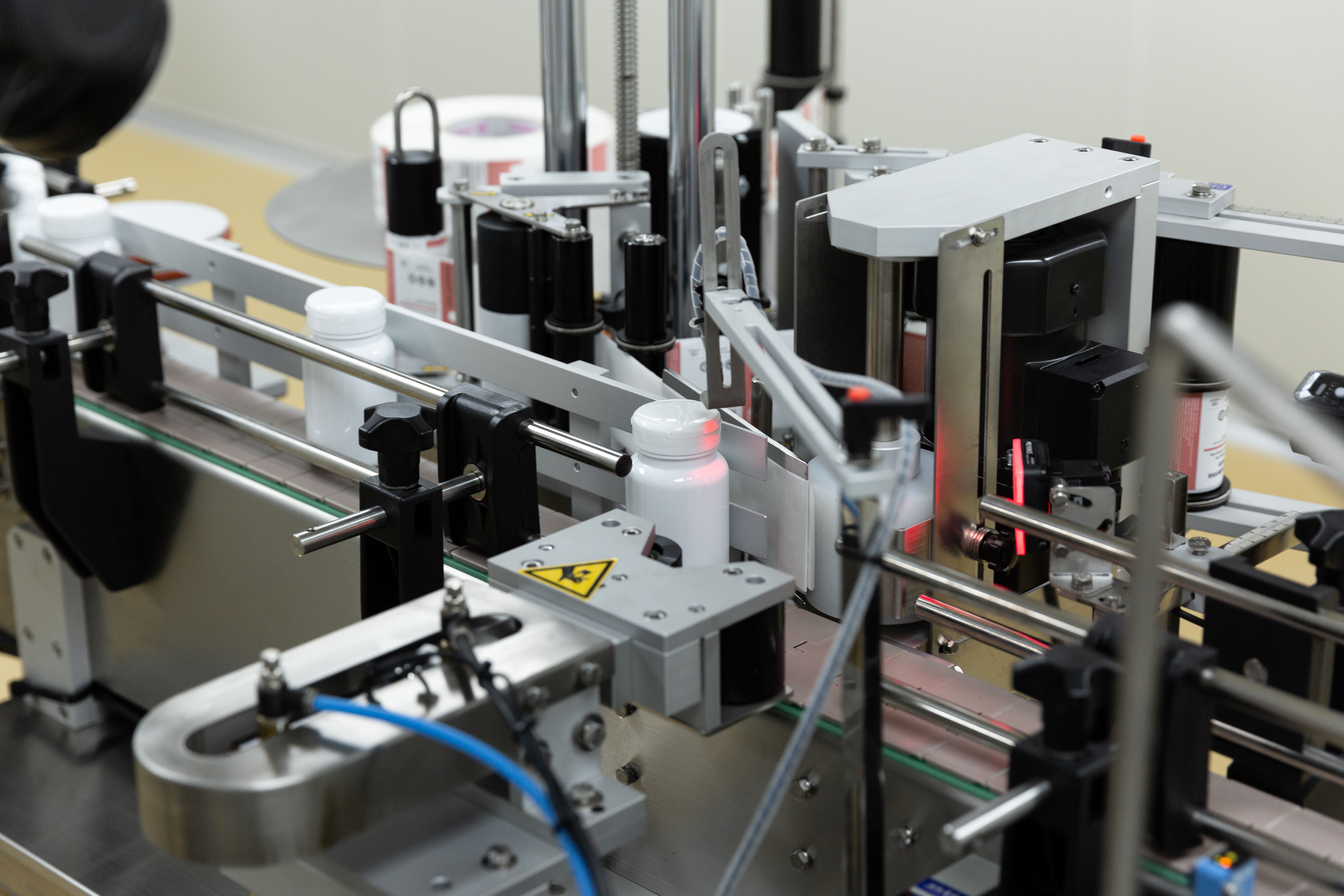

If factory certifications and staff adherence cannot fully prevent food safety issues, what additional measures can enhance food safety control? Ultimately, internal pressure alone may not ensure flawless implementation due to human nature. Therefore, external oversight is essential. Renhe Biotech is the world's first transparent manufacturing facility, allowing customers to visit anytime, observe, and monitor processes. We also upload production processes to the cloud for global review.

Food safety represents not only responsibility and obligation but also an attitude toward society and an educational opportunity for future generations. For contract manufacturers, ensuring food safety is challenging due to high costs. Nonetheless, Renhe Biotech insists on investing in AI monitoring to reduce human errors. With our renowned "Wood in the Forest" brand, we prioritize quality and safety and collaborate with experts worldwide, subjecting our operations to extensive scrutiny. Transparency in our processes allows anyone concerned to evaluate them firsthand.